“Complex applications require a high degree of specialization, consistency and quality – all this is offered by HAM crystal technology.”

Laser and precision optics

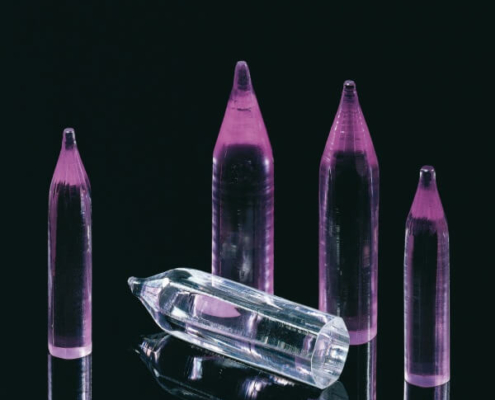

For decades HAM Crystal has been producing high-quality innovative components for solid-state lasers.

Manufacturing according to customer specifications is our strength.

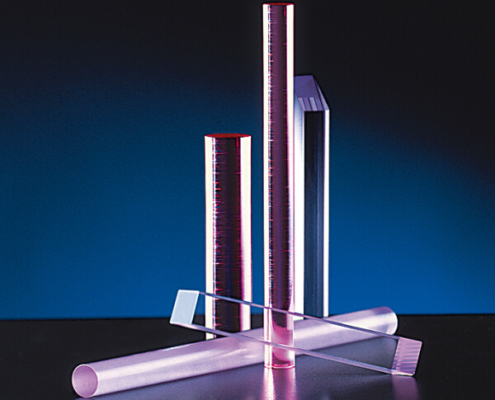

High-quality optical components made of materials such as sapphire or quartz glass, precise laser rods with highest accuracy can be found in the product range of HAM Crystal as well as the production of micro-optical components or the processing of ceramic and special materials. Thanks to the use of the latest ultrasonic-assisted drilling and grinding technology as well as glass processing using UV lasers, there are practically no limits to the shape of your component.

In addition, we offer competent and high-quality reworking and recoating of defective laser crystals.

Extract from our product range:

- Laser rods made of Nd:YAG, Er:YAG, Nd:YVO4 and many more

- Repair service for defective laser rods

- Coating of laser components (AR, HR, PR – layers with high damage thresholds)

- Pump chambers made of ceramic or special glass

- Flowtubes und Flowplates

- Lenses

- Beam splitter

- Filter

- mirrors

- Protective Glasses

- Infrared converter screens for visualization of infrared laser radiation

- Substrates according to customer specifications (quartz glass, BK7, SF11 and many more)

The processing of highly brittle special materials and resins (Ultrasonic)

The machining of highly brittle materials such as silicon, silicon carbide or hardened special glass has always been a particular challenge for the manufacturing industry, because conventional machining methods such as grinding, lapping, polishing and cutting often reach their natural limits here. On the one hand, the tools used must be very hard and abrasive, and on the other hand, these hard, ultra-brittle materials tend to produce uncontrollable chipping, which often makes the resulting workpiece unusable.

This can be remedied by the use of ultrasonic-supported special tools, which perform their work at very high rotational speeds and ultrasonic vibrations coupled into the tool. The ultrasonic oscillation provides an additive supporting pulsating additional movement at the machining zone and thus ensures clearly optimized results.

The Ultrasonic 20 from DMG used at HAM Präzision enables us to machine highly brittle materials with very high precision and exceptional homogeneity. The material spectrum ranges from silicon carbide, monocrystalline silicon and glassy carbon to hardened KG3 glass.

Tell us about your specific problem and our trained team will be happy to take care of it. We are looking forward to being at your side with words and deeds.