Our showroom in Schwendi-Hörenhausen:

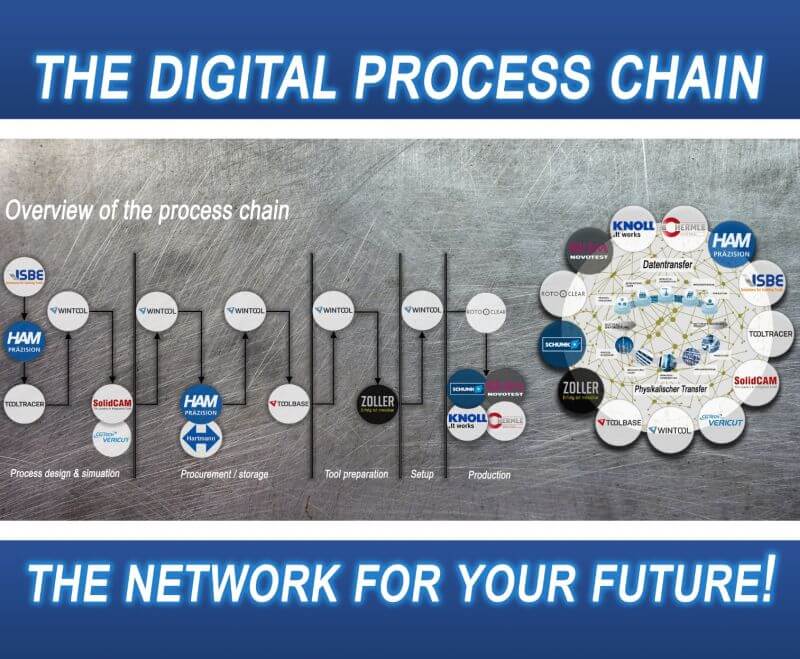

On more than 700 m² we present you a showroom that shows you ALL optimized steps along the process chain from tool model creation according to DIN 4000 to machining on the machine.

You may experience live and also virtually how processes for your production can be optimally mapped hand-in-hand and thereby exchange ideas with leading partners of the machining industry at only one place for the best possible result.

Our partners in detail:

ISBE GmbH (Itterheim Softwaretechnik), D-Stuttgart

Wasting no time in the tool design and drawing preparation and shorten the manufacturing processes?

Our showroom partner, the company ISBE GmbH (Itterheim Softwaretechnik – Consulting and Development from Stuttgart) provides us with a smart software for the tool industry.

Already implemented at our company since 2014, the Tool-Designer software helps us to digitise our production.

We benefit from the following advantages:

- Preparation of complex tool drawings including 3D model in a few minutes

- Design of solid carbide, indexable inserts and PCD tools as well as special inserts, blanks and tool holders

- Digital data according to DIN 4000 are used for manufacturing and setup on the machine

- Import and export of DXF contours and tool data

- Avoid redundancy, increase quality and shorten manufacturing processes

TCM International Tool Consulting & Management GmbH, A-Stainz

Finally order in the data chaos?

With the Tooltracer from TCM International Tool Consulting & Management GmbH; WinTool AG, Achterberg GmbH from Stainz/AUT, partner No. 2 in the new showroom, you get a grip on your master file data!

These advantages will bring you one step closer to your smart factory:

- Flawless merging of master file data from different sources

- Record consisting of geometric, commercial and application-relevant data

- Complete tool master data records without duplicates

- Use of master data in the machining process and in the core systems

- Up to 80% time saving when adapting tool master data

SolidCAM GmbH, D-Schramberg

The CAD-CAM software from SolidCAM has been implemented at our company since 2020 and it has become essential for us.

We benefit from the following advantages:

- Less programming effort due to created 3D models

- Reduced set-up time directly at the machine

- Collision control outside the machine

- Sustainability through longer tool life due to a constant load

- Patented, unique iMachining technology

- Up to 70% faster machining

VERICUT

Since 1988, CGTech’s software product VERICUT has been considered the industry standard when it comes to simulation, verification and optimization of CNC machines.

Some advantages of using VERICUT – the digital twin of your CNC machines

- Avoiding machine collisions, safe run-in of complex clamping situations

- Reduce run-in times & increase tool life

- Optimized, faster NC programs

- Reduce processing times and avoid rejects

- Increased machine capacities

- Protection of expensive production equipment

- Reduction of manufacturing costs & optimization of processes!

Wintool AG, CH-Zürich

Minimize setup times with WinTool!

Our showroom partner WinTool AG from Zurich, CH (Member of TCM Group) offers you the right tool management software for your smart factory.

The key to efficiency lies in the central machine tool library for production resources, tools and NC programs. WinTool enables optimal process planning with digital tool data.

Benefit from the following advantages:

- A central master data library

- Search and find tools – automatic disposition

- Integration of CAM systems, connection to ERP and MDE systems

- Structured, automated and retraceable data flow in your production

- Minimum setup times and maximum capacities

Toolbase

Toolbase® – the ideal tool for tools

The innovative tool dispensing systems Toolbase – Werkzeug Ausgabesysteme from the company Achterberg GmbH, 45966 Gladbeck (Member of TCM Group) impress with their reliability and versatility and are the basis of any economical production.

Automated processes ensure tool availability and avoid expensive downtimes. The mature ERP-compatible Toolbase® software ensures lean structures and efficient work processes.

The advantages of a Toolbase® system are:

- Efficient: Use of space, short distances, no search times, minimize downtimes

- Flexible: Modular construction of hardware and software and individually configurable

- Transparent: Complete tool management and cost control

- Availability: 24 hours, 7 days a week

- Cost savings: -40% process costs compared to conventional procurement / -28% tool consumption due to sensitized employees

Zoller

Be ready with the right settings and increase setup times and productivity!

We welcome our long-standing business partner E. ZOLLER GmbH + Co. KG from 74385 Pleidelsheim in our showroom.

ZOLLER offers you the right tool setting technology – completely networked for your smart factory.

Modern CNC machine tools require exact tool data in order to manufacture precisely. This data is determined with a presetting and measuring machine from ZOLLER – outside the machine. The tool data is read electronically and error-free in the machine or the tool management system and setup time is eliminated completely.

You can profit from these advantages:

- One operation with automatic tool edge recognition

- Higher productivity thanks to shorter fitting times and an increase in machine running time

- Better quality thanks to correctly preset tools – even the first part produces top quality

- Longer tool life thanks to regular review of the cutting edge quality in the ZOLLER measuring device

Rotoclear

Rotoclear combines the agile spirit of a start-up with the experience of a traditional company. Even though Rotoclear GmbH was only founded as an independent company in 2019, we can already look back on almost 40 years of product history.

The innovative products from Rotoclear all have one thing in common: they continuously create clear insights into the inside of machine tools. In other words, where the view is obstructed by liquids and particles during machining processes.

How it works. The self-cleaning viewing windows and robust camera systems use a rapidly rotating, shatterproof disk to continuously fling droplets and chips outward through centrifugal force.

The constantly clear view not only enables easy real-time control of your processes. It also allows you to visually identify the causes of potential problems – and even avoid potential errors in advance.

The two main Rotoclear solutions complement each other – and are often used in combination:

1. the Rotoclear S3 is the first self-cleaning viewing window that allows unrestricted views without a disturbing bar.

2. the Rotoclear C2 camera system gives users valuable new perspectives in 4K – even from the view of the tool itself!

Schunk

The right clamping is what counts!

For many years we have been working successfully together with SCHUNK – Superior Clamping and Gripping from 74348 Lauffen/Neckar. SCHUNK supplies us with tool holders of all kinds for our projects and their products are successfully distributed by our subsidiary Fritz Hartmann GmbH & Co. KG.

When it comes to precision, there can be no compromise. Here, the innovative and highly precise toolholding systems from SCHUNK cover a unique range.

The application is analyzed and the optimum toolholding system from SCHUNK is selected. SCHUNK guarantees maximum precision, process reliability and optimum cost control.

SCHUNK toolholders offer you the following advantages:

- Comprehensive product portfolio ranging from micro and finest machining up to heavy duty and volume cutting

- Low vibration for perfect surfaces

- High concentricity, high holding force

- Consistently high quality

- Made in Germany

Blum-Novotest

Fast, precise and incredibly process-safe!

The company BLUM-Novotest GmbH from D-88287 Grünkraut is a renowned manufacturer of innovative and precise measuring and testing technology. We are pleased that the company presents in our showroom, among other products, the worldwide unique laser measurement system for CNC machine tools for non-contact tool measurement and tool monitoring.

For this purpose, BLUM offers integrated quality control throughout the entire process chain:

- Non-contact tool measurement and tool monitoring

- Tool breakage control

- Workpiece setup

- Fast and automatic workpiece measurement

- Surface roughness measurement

- Measurement software for visualization and evaluation

With the help of BLUM’s measuring systems, error factors such as worn tools and temperature fluctuations are detected before a reject part can occur. The subsequent measurement of the finished part automatically creates the correction values for the next parts.

Knoll

We are very pleased to welcome KNOLL Maschinenbau from 88348 Bad Saulgau, the leading supplier of conveyor systems, filtering systems and pumps for metal processing, as our 10th showroom partner.

We have been using KNOLL filter systems successfully in our production for many years.

The KNOLL minimum quantity lubrication system AerosolMaster ™ is suitable for almost all manufacturing processes with geometrically determined cutting edges. The unique aerosol dry lubrication ensures minimized heat generation and eliminates the need for additional cooling. KNOLL machines are suitable for both simple and complex machining processes.

Benefit from many advantages with aerosol dry lubrication:

- Nearly dry machining – low cleaning effort for parts and machines

- Longer tool life

- Tool protection due to reduced heat generation

- Very fine and homogeneous aerosol – for high speeds up to 45,000 rpm

- Oil and air pressure appropriately adjustable

- Low-loss lubrication due to low oil consumption

Hermle

Berthold Hermle AG, D-78559 Gosheim, Germany, represents high-performance and highly innovative machining centers and their automation solutions worldwide and is a heavyweight in the machining industry.

In our showroom you can admire the compact and space-saving C 12 machining center live and in action – with maximum efficiency and highest precision.

- Uncompromising precision in manufacturing which also affects your components

- Reliable 5-axis simultaneous machining for a wide variety of applications

- Long-term accurate reproducibility of components by a high manufacturing depth

Helmut Diebold GmbH & Co.

Diebold from Jungingen is a worldwide leading manufacturer of shrink fit machines and shrink fit chucks for all applications.

In our Smart Factory, the US 1100 shrink fit machine and the JET SLEEVE 2.0 and ULTRAJET 3.0 tool holders are used. The innovative coolant supply achieves a higher tool life and productivity.

Diebold also offers a mobile service with three Demo Vans. These Demo Vans are equipped with all Diebold products and present their products live at the customer’s site.

We are pleased that we were allowed to equip the Diebold Demo Vans with our HAM tools.

NUM AG

With its numroto grinding software, NUM AG has been a successful trendsetter in high-precision tool grinding for many years.

In the HAM showroom, the numroto grinding software is successfully used on the Vollmer VGrind argon.

The advantages are:

- Logically structured user interface ensures intuitive handling

- Edit a wide range of different tools

- Finding the optimal solution economically and functionally

- 3D representation of tool and machine

- Collision monitoring

Vollmer Werke Maschinenfabrik GmbH

Maximum sharpness for tools in production and service: this is what the name Vollmer stands for. The family-run company from Biberach sees itself as a solution provider for its customers worldwide.

The Vollmer VGrind argon is used in the HAM showroom.

We benefit from the following advantages:

- High flexibility thanks to the internal loading system with automatic collet change

- Very short set-up times, very good dimensional accuracy

- Tools can be round-ground and spiral-ground in a single clamping operation

Hartmetallwerkzeugfabrik Andreas Maier GmbH

The company HAM Präzision in Schwendi-Hörenhausen is the host of the showroom.

The product portfolio includes drills, reamers, milling cutters, countersinks, WSP tools in PCD and CBN as well as special tools for PCB production and for the dental and medical sectors. In addition, we manufacture innovative components for solid-state lasers in the Crystal Technology division.

The areas of application for our products are diverse.

Among our major customers are leading companies in the

- Automotive and supplier industry

- Mechanical and plant engineering

- Aerospace industry

- Tool and mold making

- Printed circuit board industry

- Dental and medical technology

- Laser and precision optics

When can we welcome you in our showroom?

Contact us using the form below.

Important Links

Trade Fairs / Events

Newsletter

Address / Contact

Andreas Maier GmbH

Stegwiesen 2

D-88477 Schwendi-Hörenhausen

Germany

Phone: +49 7347 - 61-0

Fax: +49 7347 - 7307

e-mail: info@ham-tools.com

Contact form