HAM deep hole drills are used even more successfully – thanks to the special polishing process with high gloss effect.

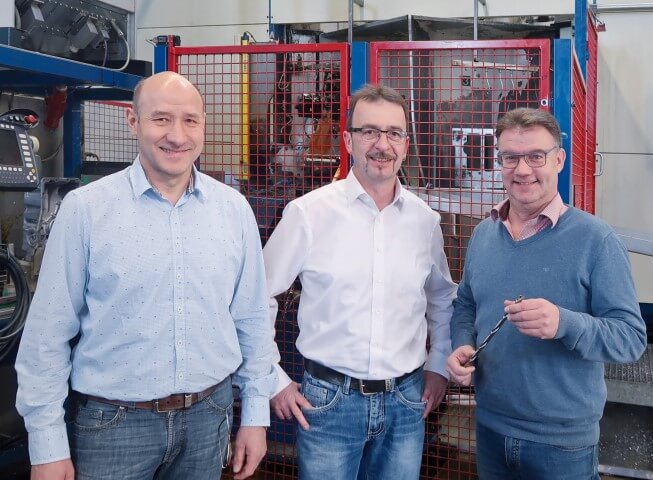

With HAM, Stöferle from Laupheim-Untersulmetingen has had a competent partner and tool supplier at its side since 1995. HAM always makes the production even more efficient with innovations and new products.

Mr Reinhard Stöferle, operation manager of the Stöferle GmbH, had problems with uncontrolled tool breakage while using a straight fluted drill with a 4 guide chamfer Ø 8.5 mm in an oil pan. He asked HAM to develop a solution for this problem .

The process was analysed by a HAM technician and a similar tool with an optimized geometry for the entry into a precast hole and an oblique exit was designed. The result was a higher process reliability and a considerable increase of tool life from 7,000 to 15,000 parts. Nevertheless, the premature tool breakage still occurred occasionally

On the recommendation of HAM a deep hole drill for aluminium, the standard article 30-2580 Ø 8.5 mm was tested. With this deep hole drill 15 x D with interior coolant, 15° helix, 4 guide chamfer, 2 teeth and the special surface treatment the tool life was doubled again to 30,000 parts. The premature tool breakage no longer occurred. A positive side effect was an increase of the feed rate, which also shortened the cycle time.

For another component there was a similar problem with a single-edged deep hole drill Ø 15.9 mm and a drilling depth of about 250 mm. HAM also convinced with a deep hole drill for aluminium similar to the HAM standard with an overall length of 330 mm and the special surface treatment. The feed rate could be doubled from 0.2 to 0.4 mm/rev, which was a considerable reduction in cycle time. The drilling process is now stable – much to the pleasure of Mr Stöferle.

Meanwhile several HAM deep hole drills for aluminium are successfully used at Stöferle. ”The quality, the price-performance-ratio, the delivery times, the competence and the tool know-how are very good”, says Mr Reinhard Stöferle. ”Since using the HAM deep hole drills, no uncontrolled tool breakages occur any more.”

Stöferle also relies on HAM for other applications.