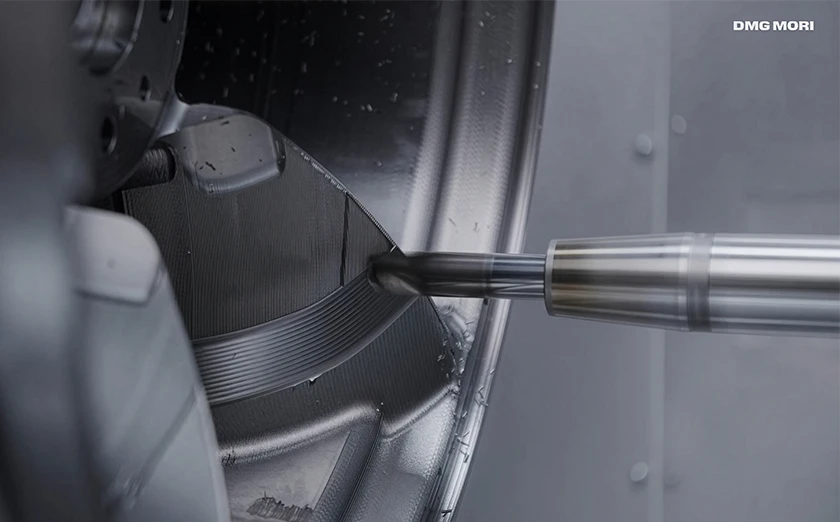

JP Performance titanium rim: From a 400 kg titanium block to a high-end rim – our tools in action

The JP Performance titanium rim is a globally unique project. A rim made of Grade 5 titanium – a material otherwise used in aerospace – was manufactured for the legendary Jaguar E-Type. It took over 160 hours of machining time to transform the 400 kg raw block into the finished 18 kg rim. The project began through a collaboration between Ladermanufaktur GmbH and JP Performance. We were directly involved as a tooling partner and played a decisive role in the manufacturing process with our high-performance titanium milling cutters.

Material & starting point: Grade 5 titanium

The journey to creating JP Performance titanium rims begins with a solid 400 kg block of titanium. Grade 5 titanium impresses with its high strength, corrosion resistance, and low thermal conductivity. These material properties make machining particularly challenging. Without the milling cutters specially developed for titanium, the transformation from raw block to high-end rim would not have been possible. Our tools ensured maximum stability, process reliability, and precision.

Manufacturing & machining: 160 hours of high-end machining

The production of the titanium rim is a prime example of high-end machining. Creating each rim from a 400 kg block of titanium requires over 160 hours of machining time. The process uses the following:

- 5-axis milling, including simultaneous machining

- CAM software: SolidCAM with strategies such as iMachining 2D/3D

- Machining methods: High-speed machining

Developed for extreme conditions, our titanium milling cutters ensure precision when machining complex geometries. Tool lengths of up to 400 mm placed special demands on stability and vibration damping.

Design & aesthetics of the titanium rim

The rim design is turbine-like, with deeply machined spokes and clearly defined contours. It combines the classic elegance of the Jaguar E-Type with state-of-the-art high-end manufacturing. Tailoring each contour to the capabilities of the tools and the machining strategy ensures precision. The result is technical perfection and aesthetics in a unique piece.

Technical challenges in titanium machining

Experts consider titanium a particularly challenging material for machining. The deep pockets and long milling cutters (up to 400 mm) create vibration risks and stability problems. The high strength and low thermal conductivity increase the risk of tool breakage and material overheating. In addition, the enormous material removal from the 400 kg raw block to the final weight of 18 kg must be precisely controlled.

Our solution consisted of optimized tool paths, adaptive cutting parameters, and continuous process monitoring. Every decision was based on our direct expertise in the manufacturing process.

Source: DMG MORI / YouTube, Video „JP Performance x DMG MORI Teaser: Machining a Complete Titanium Rim“, https://www.youtube.com/watch?v=vRAN-JgLzEs

Project facts at a glance

- Material: 400 kg titanium grade 5

- Processing time: >160 hours per rim

- Machine: DMG MORI DMU 85 H monoBLOCK

- Dimensions: Ø 560 mm x 371 mm

- Partners: HAM Präzision, DMG MORI, SolidCAM, Ladermanufaktur GmbH, AVANTEC Zerspantechnik, Rosswag Engineering

Conclusion: High-end rim from JP Performance

The titanium rim from JP Performance is a unique piece that is one of a kind worldwide. Our tools and expertise were crucial to its implementation. The project combines high-end machining, material expertise, and design at the highest level.