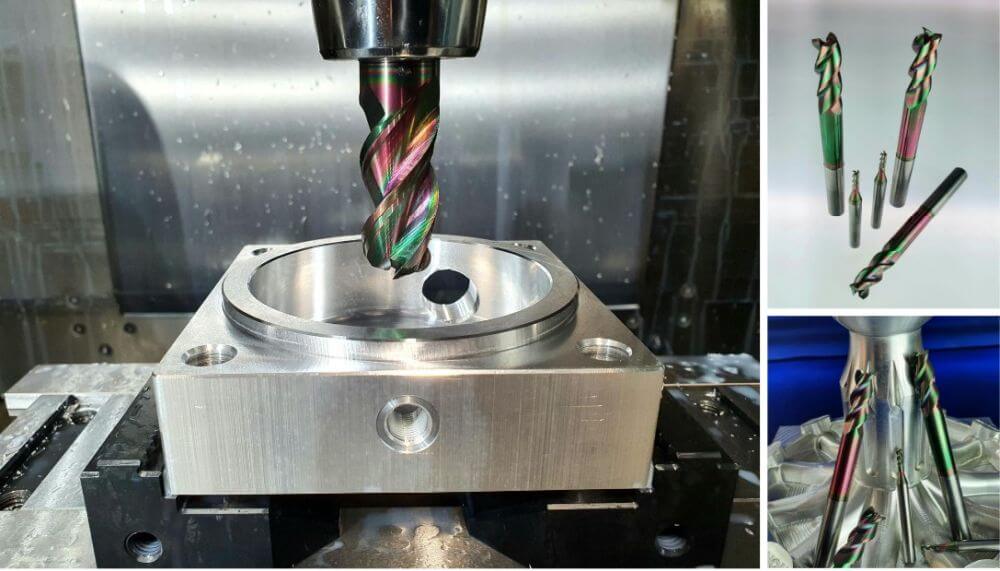

To meet the increasing demands of our customers from now all HAM milling cutters with the coating specification TA-AL will get our NEW rainbow-colored carbon coating.

Read more

To meet the increasing demands of our customers from now all HAM milling cutters with the coating specification TA-AL will get our NEW rainbow-colored carbon coating.

Read more

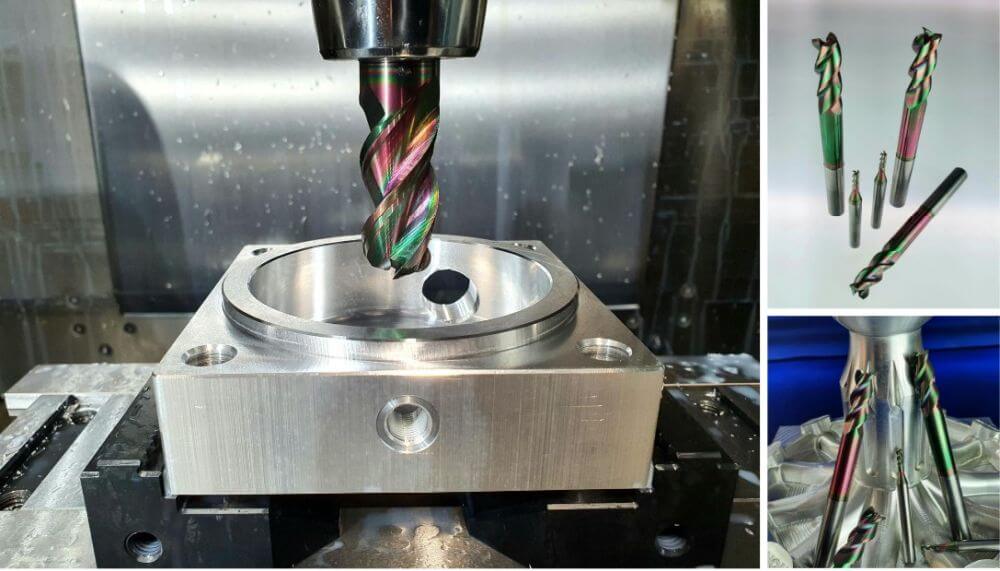

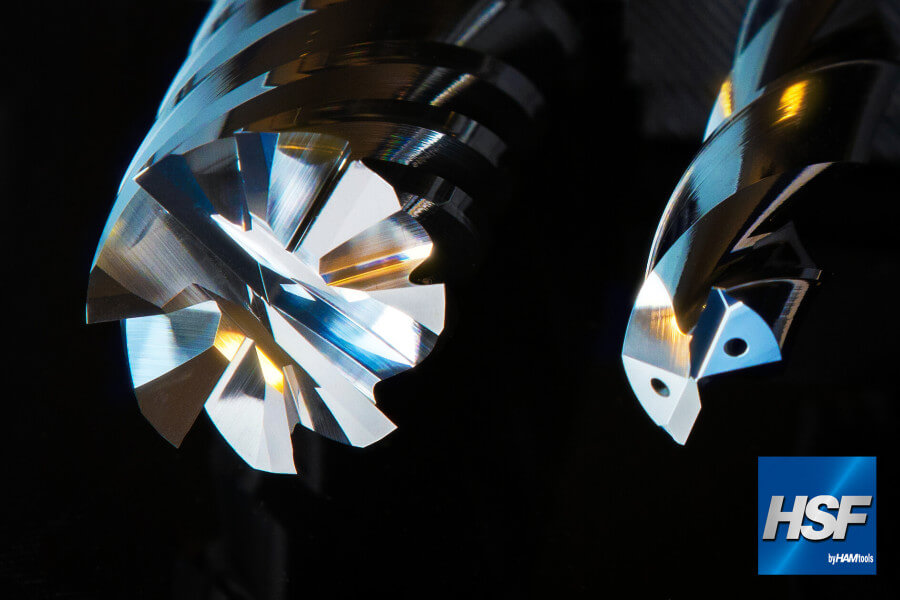

Special-polishing process HYBRID SURFACE FINISHING

With the new Hybrid Surface Finishing HAM is launching a polishing process in which all tool surfaces are hyper smooth polished with defined and reproduceable main and secondary cutting edge preparation.