Special-polishing process Hybrid Surface Finishing

Special-polishing process HYBRID SURFACE FINISHING

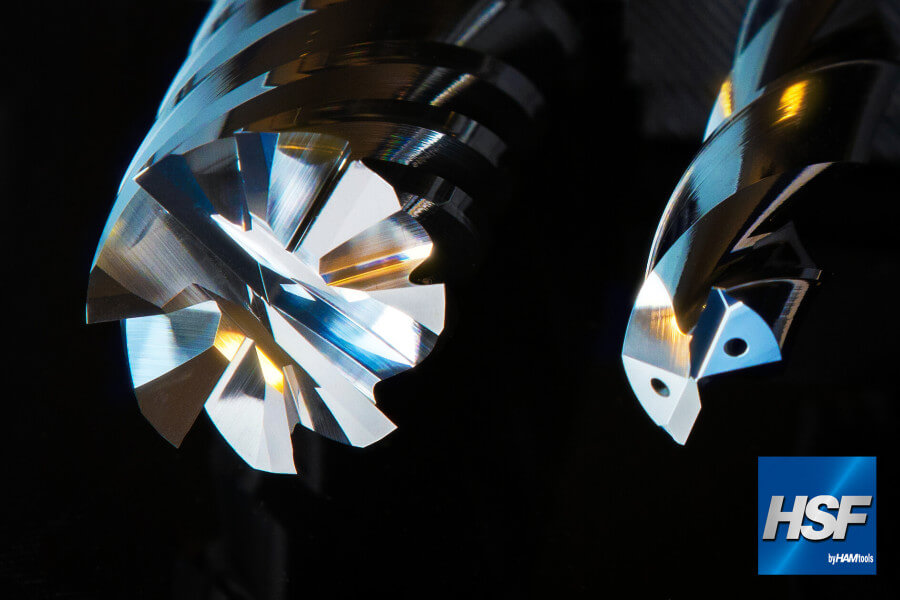

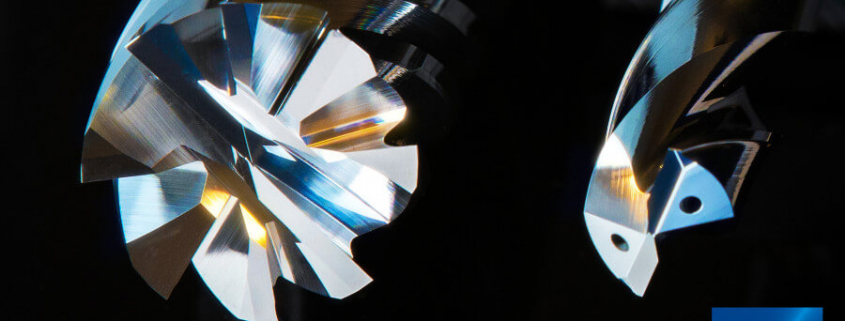

With the new Hybrid Surface Finishing HAM is launching a polishing process in which all tool surfaces are hyper smooth polished with defined and reproduceable main and secondary cutting edge preparation.

HAM has been developing high-performance tools for the machining of all conventional materials for many years. This also includes modern materials such CFRP, titanium, honeycomb, aluminium and composite sandwich materials.

One of the biggest challenges with modern materials is the machining. For example, CFRP is highly abrasive and titanium is a long-chipping material with very poor thermal conductivity. The result is a very high temparature on the tool cutting edge, which leads to enormous tool wear and consequently also to a shorter tool life.

However, temperature developments on the cutting tool and in the workpiece to be machined have to be avoided. Another goal is to avoid built-up edges – i.e. material adhesion or welding on the cutting edge of the tool and stuck of chips in the flute which would lead to a tool breakage.

For the cutting tool the following factors determine success or failure:

- The best tool geometry in appropriate grinding quality (depending on material and application)

- Die The polishing of the flute for an optimal chip removal (reduction of friction forces)

- Preparation and homogenization of the cutting edge, designed for the material (protection of the cutting edge, prevention of built-up edges)

- Wear protection coating (to reduce generation of heat and increase life cycle time)

To meet the market requirements, HAM has developed a hybrid technologically highly complex solution for surface treatment – Hybrid Surface Finishing. With this treatment a reproducible and process-safe cutting edge homogenization takes place with simultaneous polishing of all tool surfaces in the cutting area.

Advantages:

- Variable cutting edge rounding between 4-20 µm depending on the material

- Reducing of built-up edges

- Optimal chip removal

- Homogeneous and reproducible surfaces can be produced

- Higher cutting speeds and feed rates are possible

- Reduced cutting and spindle forces

- Less heat generation on the tool, workpiece and on chips

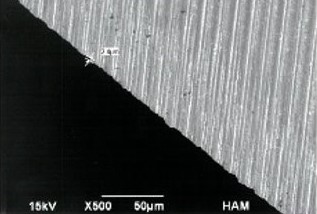

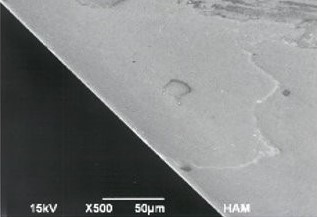

- Surface roughness

before 0,1 to 0,15 µm –> after 0,008 to 0,015 µm - Chippings of the major and minor cutting edges < 1 µm

Here you can find our brochure on HSF – Hybrid Surface Finishing

Are you interested? Please contact us!

HAM GmbH

HAM GmbH

HAM GmbH

HAM GmbH