Understanding and implementing complete turning-milling machining: production without manual reclamping is this simple

Turning, milling, drilling, reaming, threading, measuring – all in a single integrated process. Sounds like the future, but it has long been a reality in modern manufacturing companies. Complete turning-milling machining combines high-precision machining steps into an efficient process that saves time, reduces errors and sustainably improves processes.

This is exactly what we demonstrated in our workshop. How CAM programming, tool strategy and machine concept combine to form a coherent solution. From the digital model to the finished component. With real workpieces, real machining strategies and real results.

In this article, we take you on a practical journey. You will learn how we transform complex requirements into clear solutions. And you will see why tool selection, CAM system and process thinking are now more decisive than ever for quality and competitiveness. Welcome to the world of complete turn-mill machining. Welcome to the “Drevolution“.

From past challenges to today’s precision

Anyone involved in modern turn-mill complete machining today should understand the hurdles that had to be overcome in the past. The production of complex components often began with the creation of elaborate 2D drawings. Every line, every dimension had to be interpreted precisely. This often resulted in ambiguities that developed into real problems in production.

Programming was also carried out directly on the machine. This was not only time-consuming but also blocked valuable machine running time. Any manual input error could lead to downtime. In addition, tools were often not managed centrally. Whether a suitable tool was available or even suitable at all could often only be determined during set-up. In many cases, the first part produced only served as a test piece – rejects were almost inevitable.

Digital thinking. Made efficiently.

Today, things look very different. Modern production begins with a well thought-out 3D model, for example in Step or SolidWorks format. It is no longer programmed directly on the machine, but using powerful CAM systems that also enable simulations. Even before the first cut is made, it is possible to check how the tool will behave in the installation space, whether there are any collisions and whether all the machining steps mesh properly.

Tool data, geometries and cutting values are available centrally. Customers are increasingly demanding digital twins to supplement their own systems, for example for CAM programming or collision-free assembly planning. Tool management is thus becoming an integral part of a digitized, end-to-end process.

At HAM Präzision, we live exactly what we teach in our workshops. Our goal is not only to understand processes, but to consistently optimize them. Error prevention, maximum process reliability and short production times are our daily focus. After CAM programming, we can go straight to the machine – without rejects, without time-consuming set-up, without long searches for the right tool or room for interpretation of drawings. This end-to-end process is a decisive advantage, especially in our one-off and small series production.

The advantages speak for themselves: machine downtimes are avoided, tools are centrally managed and available at all times, manual programming errors are a thing of the past. The result is an end-to-end manufacturing process that combines maximum precision with impressive efficiency. What we are experiencing is not a slow change, but a noticeable further development in machining. A new way of thinking. A real turning revolution.

What “Drehvolution” means to us

For us, “Drehvolution” describes a holistic approach that begins long before the first chip – namely, with the design of the tool. In this early phase, we lay the foundation for precise, economical and consistent production. Our goal is to design each process step in such a way that maximum precision goes hand in hand with high efficiency. This includes the consistent use of digital tool data and well thought-out process planning right from the start.

The demands on production are constantly increasing. Customers expect shorter delivery times, consistently high quality and reliable prices. At the same time, qualified personnel are becoming increasingly rare. We meet these challenges with innovative solutions that closely interlink and coordinate planning, production and tool management.

Complete machining as the key to efficiency

Modern complete turning-milling machining combines all work steps – turning, milling, drilling, threading, deburring and measuring – in a single machining center. The process runs continuously with just one reclamping, supported by automated loading and unloading systems such as bar or gantry loaders for a smooth material flow.

A look at the time involved shows the progress: whereas modeling, drawing creation, checking and programming often used to take more than 800 minutes, it now takes around 500 minutes with CAM programs and digital tool data. Manual programming and downtimes in particular are eliminated, saving several hours of time.

This efficiency is the result of high-performance CAM systems in combination with central tool management. Tools are digitally recorded and available at all times, minimizing machine downtimes and significantly reducing sources of error.

Additional challenges and solutions

In addition to technical implementation, modern manufacturing presents numerous challenges that can be specifically addressed through integrated turn-mill complete machining. In terms of economic efficiency, every minute counts today. The time from quotation to finished product must be kept as short as possible. At the same time, fewer personnel are employed, but they have to take on more responsibility and tasks.

Competitiveness is also under pressure. Delivery deadlines must be met, prices must be calculable and processes must be planned. Automated tool management provides support here, as it ensures that all operating resources are available at all times. This avoids unnecessary machine downtime due to missing tools.

Digitalization offers enormous potential, but is not yet fully exploited in many companies. Although industry four point zero is frequently mentioned, full implementation often fails due to limited financial resources, a lack of specialists or the complexity of the systems.

Added to this is the increasing time pressure in day-to-day business. Delivery times are getting shorter and customers are making changes at ever shorter notice. Sometimes adjustments even reach us during ongoing production. Without digital models and precise CAM programming, such changes would be almost impossible to implement realistically.

And finally, the focus is on quality. Optical and functional repeatability is essential today. Automated deburring ensures that every manufactured part meets the exact same requirements and remains constant in terms of form and function.

From digital model to the integrated process

The work begins on the screen long before the chips start flying. The basis for stable complete turn-mill machining is a complete 3D model of the component. This can be integrated quickly and directly into SolidWorks and forms the basis for CAM programming. This allows machining strategies to be simulated, checked and specifically adapted long before the workpiece reaches the machining center.

However, a challenge arises with models that are not designed for mid-tolerance. This is because the CAM system implements exactly what the model specifies. For example, it does not automatically recognize whether a diameter is between plus zero point one and plus zero point two. In such cases, we therefore specifically program a grinding allowance that appears to be a deviation in the simulation, but corresponds exactly to the target dimension in actual production.

For consistent and precise complete machining, all components must be coordinated with each other. The machine with its kinematics and cooling functions, the workpiece clamping, the tool holder, the CAM strategy, the selected cutting values, the type of cooling and, of course, the tools used themselves. Whether PCD or solid carbide, whether with special cutting edge geometry, coating or coordinated helix angle – every detail contributes to process reliability and repeat accuracy. A stable, reproducible production process can only be achieved when everything works together.

Turning-milling complete machining in live application

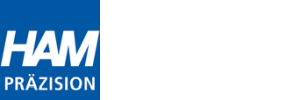

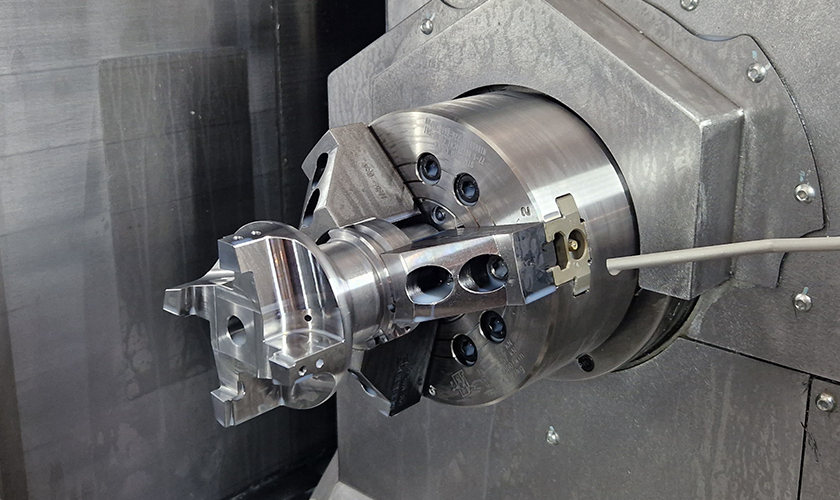

This interaction was demonstrated live during our workshop. The focus was on the complete machining of a base body for a PCD tool made of steel. From cutting, turning, milling, drilling, reaming and threading to automatic deburring and measuring, every step was carried out directly on site.

A Mazak Integrex i 100H S, equipped with the Mazatrol control system, was used. For workpiece clamping, we used gripper jaws on the main spindle and specially machined jaws on the counter spindle. Tool clamping was ensured by Capto C6 in combination with hydraulic expansion technology. Classic emulsion ensured reliable cooling.

A particular highlight was the integrated measurement during the machining process. The TC62 3D touch probe from Blum Novotest was used in this configuration for the first time. The measurement data was processed directly and fed back to the machine for correction. The result was a consistently precise component – with no manual reworking and no loss of time.

The CAM programming was implemented with SolidCAM. Among other things, powerful strategies such as iMachining were used, which enable uniform machining with optimum loading of the cutting edges. The tools we used were precisely matched to the material and the machining task. The cutting material, cutting values, geometry and surface technology interlocked perfectly.

The result was a functional, dimensionally accurate basic body – completely manufactured in a single clamping operation. Fast, safe and with maximum precision.

🎥 Watch the video to see what this process looks like in reality. Immerse yourself in the practice of modern turn-mill complete machining – precise, efficient and live.