CAD/CAM grinding in practice: From digital twin to ready-to-use special tool

In machining, nothing works without the right tool. If you want to manufacture a component, you need a cutting tool that is suitable for the task. We rely on modern CAD/CAM systems right from the planning stage – in particular CAD/CAM grinding – to make processes more efficient and easier to plan. The digital process chain has long been a reality at our HAM Performance Center (HPC) too.

We usually fall back on tried-and-tested standard solutions. Catalog tools are readily available and have proven themselves reliable in many applications. But sometimes these tools reach their limits. Not every machining operation can be carried out economically or technically in a sensible manner using these tools.

What then? The answer often lies in customized solutions. Special tools offer exactly what standard tools cannot. They are individually tailored to the component and enable machining operations that would otherwise not be possible.

What often makes us hesitate when it comes to special tools

Special tools offer many advantages. Nevertheless, the decision to opt for a customized solution is not always easy. The most obvious reason is the price. Especially with smaller quantities, the question quickly arises as to whether the investment is worthwhile at all.

Added to this is the necessary expertise. Complex geometries and special requirements call for technical understanding and experience – not every company has this available in-house. Delivery time also plays a role. Special tools first have to be developed and manufactured, which takes time. The longer it takes for the tool to arrive, the later the component can be produced.

Another point is the coordination effort involved. Requirements must be discussed, drawings checked, and queries clarified. This ties up resources and costs time – a real bottleneck, especially in tight project phases.

And yet, those who opt for special tools have a lot to gain. Customized solutions enable machining operations that would not be possible with standard tools. They save time, improve quality, and make processes more efficient.

Why special tools are worthwhile

Combination solutions allow several machining steps to be combined. This saves machining time and reduces tool changes – a clear advantage in terms of non-productive time. At the same time, the risk of misalignment or inaccuracies is minimized, as machining is carried out in a single operation. The result: higher quality.

Space is also saved in the tool magazine, which increases flexibility – especially when changer space is limited. All these factors contribute directly to cost-effectiveness. The additional expense is quickly recouped, especially with complex or recurring components.

And what about the typical concerns? The costs are offset by efficiency and precision. The necessary specialist knowledge is simplified by the ISBE Sketcher and standardized in accordance with DIN standards. The coordination effort is reduced by digital processes. And thanks to our HAMmer FAST LANE, long delivery times are a thing of the past – complex special tools are designed and manufactured within minutes.

More than just the right tool

A good tool alone is not enough to manufacture a component efficiently and precisely. The entire process is crucial – and it begins long before the first chip is cut.

Many components interact during production. The machine, clamping, CAD/CAM programming, cooling, and tools must be perfectly coordinated. Only when all components work together harmoniously can a stable and economical overall process be achieved.

There is also more to the “Tool” module than meets the eye. After all, what makes a normal tool a perfect tool? It’s the details – from the geometry and coating to the coordination with the material and machining strategy.

What makes a tool perfect

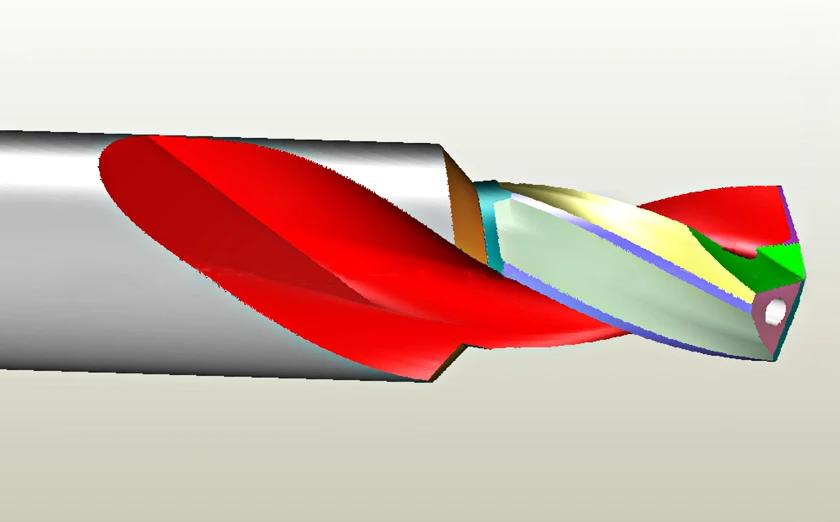

A perfect tool starts with the right material. The first crucial point is selecting the appropriate carbide. Carbide is a sintered material whose main components are tungsten carbide as the hard material and cobalt as the binder. Depending on the intended use, other carbides are added to specifically modify the properties.

Due to the high sintering temperature of around 1500°C, carbide is naturally extremely heat-resistant – and, as the name suggests, very hard. The grain sizes range from less than 0.2 µm in the nano range to over 6.0 µm in the coarse grain range. This means that the mechanical properties also vary greatly. At HAM, we generally use carbide grades ranging from ultra-fine to fine grain in order to achieve an optimal combination of hardness, toughness, and wear resistance.

Bevor das Werkzeug beschichtet wird, durchläuft es unsere eigene Oberflächenbehandlung: das Hybrid Surface Finish (HSF). Dabei wird der Spanraum poliert, um den Späneabtransport zu verbessern, und die Schneidkante gezielt verrundet – für mehr Stabilität und längere Standzeiten.

Before the tool is coated, it undergoes our own surface treatment: Hybrid Surface Finish (HSF). This involves polishing the chip space to improve chip removal and specifically rounding the cutting edge for greater stability and longer service life.

Various hard coatings are used, depending on the application and material. Examples include:

- TiAlN / TiSiN: Multilayer or nanocomposite

- TiAlN: Monolayer or multilayer

- AlTiN supernitrides: Nanocomposite or nanolayer

- ta-C (DLC): Tetrahedral, amorphous carbon layer – also known as “rainbow layer”

A clear example of this is dome polishing. This technique makes the structure of a TiAlN-based multilayer coating visible—a process that not only looks impressive, but also provides valuable technical insights.

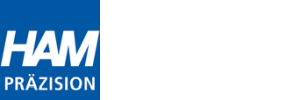

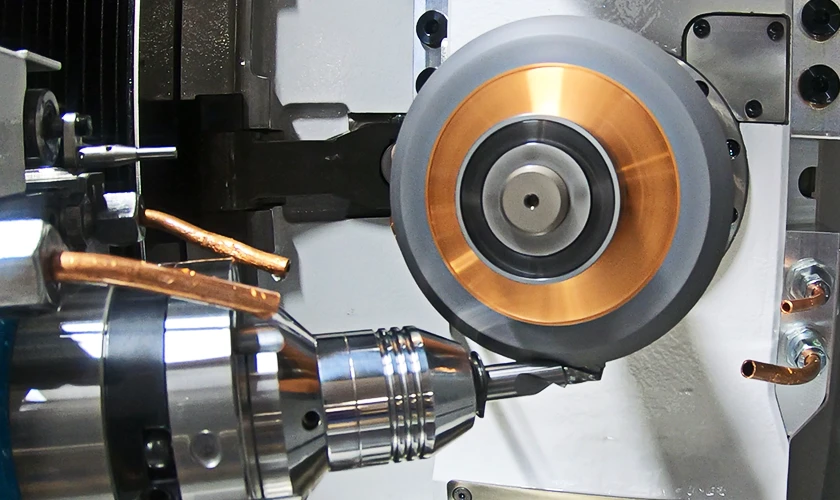

Grinding the perfect tool – a process with many components

A perfect tool is not only the result of good materials and precise geometry. Grinding itself is also a complex process in which many factors must interact.

It all starts with selecting the right grinding wheels. This is followed by programming – a step that often takes a lot of time. With CAD/CAM Grinding, tools can be designed quickly and easily and tracked digitally throughout the entire process. Parameters that have already been entered when preparing the quote do not need to be entered multiple times. This saves time and reduces sources of error.

The grinding machine must also reliably implement the required process parameters. And to ensure the right quality, precise measurement technology is needed. Modern systems measure the tool during the process – with micrometer precision—and compensate automatically. This minimizes the influence of human error and ensures a stable, uninterrupted process.

To ensure that this process runs smoothly, all of our partners work hand in hand:

- Vollmer VGrind infinity as a flexible grinding machine

- ISBE Sketcher for tool design

- BLUM laser measuring bridge for in-process measurement

- and HAM‘s tool expertise

Implementation in practice: From component to solution

Unser Beispielbauteil: ein pneumatischer Zylinderboden. Für das G1/8-Gewinde fehlten Wechslerplätze – die Lösung war ein Sonder-Stufenbohrer, der vier Operationen auf zwei reduziert.

Our example component: a pneumatic cylinder base. There was not enough space for the G1/8 thread – the solution was a special step drill that reduced four operations to two.

Instead of centering, drilling, countersinking, and cutting, machining is now performed in a single operation. The core hole and countersink are combined, and the thread is milled and checked. This saves time, reduces tool changes, and increases efficiency.

Key technical data for the component:

- Material: EN AW-2007

- Dimensions: 110 × 110 × 40 mm

- Machine: Hermle C12U

- Control: Heidenhain TNC 640

- Workpiece clamping: LANG zero point clamping system

- Tool clamping: Schunk HSK-A63

- Cooling: MMS, KSS

Technical data of the special tool:

- Material: VHM K40 10

- Dimensions: Ø12 × 103 mm

- Grinding machine: Vollmer VGrind infinity LINEAR

- Control: NUMROTO

- Workpiece clamping: Schunk hydraulic expansion chuck

- Measuring instruments: BLUM TC 76-N, BLUM LC50

Practical implementation: Live demonstration in the workshop

Our compact video shows how all the process components described interact in reality. From the digital design of the special step drill to precise grinding and final use on the pneumatic cylinder base—every step is part of a well-thought-out, efficient, and proven process.

The live demonstration clearly shows that with the right combination of CAD/CAM technology, machine expertise, and tooling know-how, even complex requirements can be implemented quickly and economically.